Of all the planet-warming greenhouse gases human activity releases into the atmosphere, carbon dioxide is the Most Significant EmissionAs such, experts have suggested that, in addition to drastically lowering our fossil fuel use, we should activly remove carbon dioxide (co2) from the atmosphere. What’s Known as Carbon Capture Technology, however, is usually expensive and/or energy-intense, and necessitates carbon storage solutions.

Now, Researchers at Stanford University Have Proposed a Surprisingly Practical Strategy: Make Rocks do it for us.

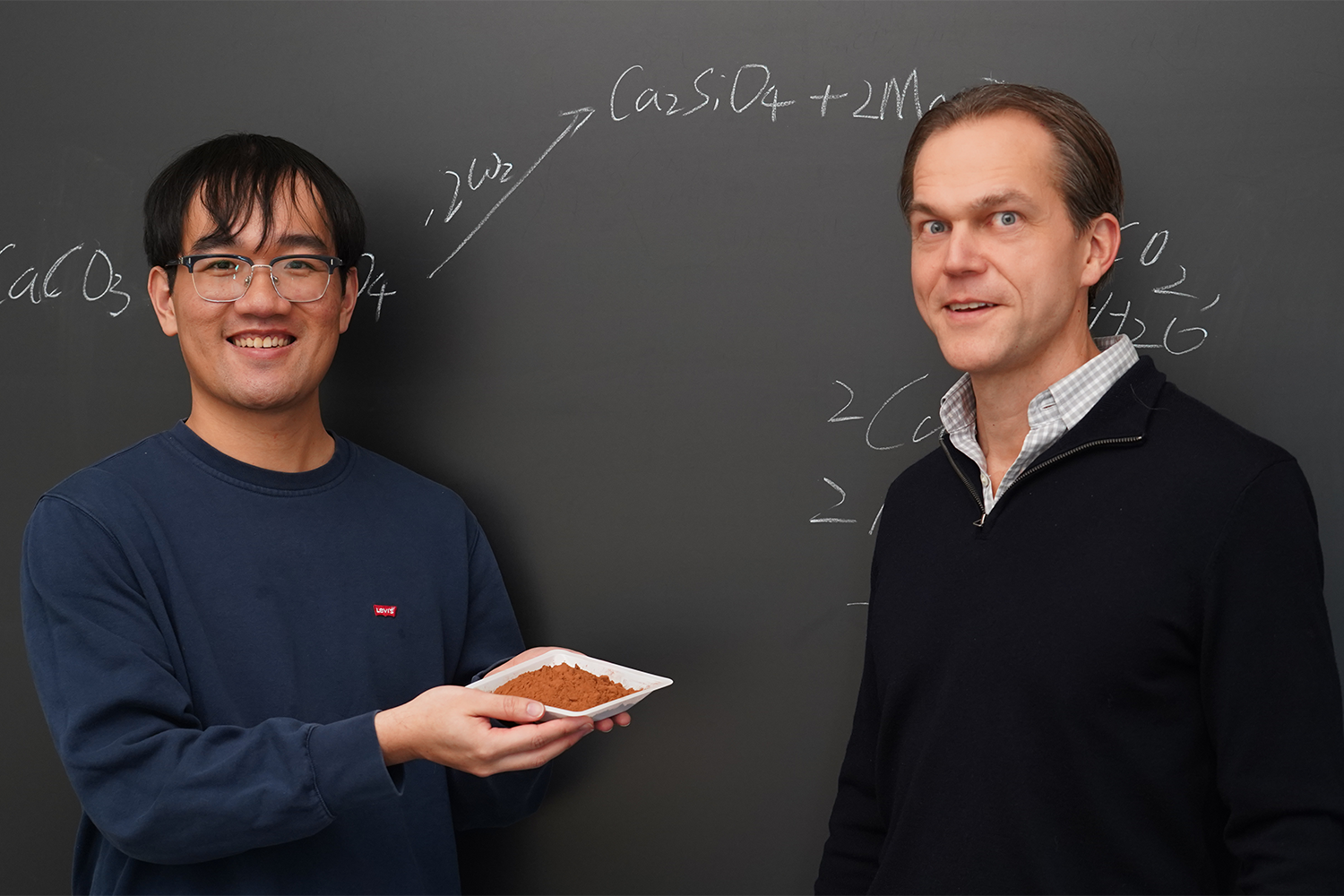

They’re not kidding. Stanford Chemists Matthew Kanan and Yuxuan Chen Have Developed A Process that Uses Heat to Transform Minerals Into Materials that Absorb Co2 – Permanently. As detailed in a study Published Wednsday in the Journal NatureThe process is practical and low-cost. Additionally, Kanan and Chen’s very helpful Rocks could satisfy the needs of a Common Agricultural Practice, Hitting Two Birds with One Stone.

“The Earth has an inexhaustible supply of mineals that are capable of removing co2 from the atmosphere, but they just don’t react fast fast enough on their Own to their Own to CountCon Kanan, The Senior Author of the Study, said in a stanford statement“Our work solves this problem in a way that we think is uniquely scalable.”

For decades, scientists have studied ways to accelerate some Rocks’ Natural Absorption of Co2, A Process Called Weathering Weathering that can takes Kanan and chen seem to have cracked the code by converting common slow-sheetering menrarals called silicates into fast-vegetarian menrarals.

“We Envisioned a new chemistry to activate the inrt [not chemically reactive] Silicate mineals through a simple ion-exache reaction, ”Chen explained. Ions are atoms or groups of atoms with an Electrical Charge. “We Didn’T Expect that it would work as well as it does.”

Kanan and Chen was inspired by cement production, where a kiln, or furnace, converts limestone (a -seasonary Rock) Into a reactive chemical compound calcium oxide, which is given is then Mixed With Sandy. The chemists replicated this process, but swapped sand out for a material called a magnesium silicate. Magnesium silicate contains two menrarals that, with heat, exchanged ines and turned into magnesium oxide and calcium silicate: minerals that weather qiqly.

“The process acts as a multiplier,” said Kanan. “You take one reactive mineral, calcium oxide, and a magnesium silicate that is more or less inrt, and you generate two reactive minerals.”

To test their results, kanan and chen exposed wet calcium silicate and magnesium oxide to air. They turned into carbonate mineals -the result of weathering – withhin weeks to months.

“You can imagine spreading magnesium oxide and calcium silicate over large area to remove co2 from Ambient Air,” Kanan Said. “One Exciting Application that We’re Testing Now is adding them to Agricultural Soil.” This application could also be Practical for Farmers, Who Add Calcium Carbonate to Soil when it’s it’s too acidic: a solution called Liming.

“Adding our product would eliminate the need for Liming, Since Both Mineral Components Are Alkaline [basic, as opposed to acidic]”Kanan explained. “In addition, as calcium silicate weaths, it relaic in a form that the plants can take up, which can improve crop yields and resilience. Ideally, Farmers would pay for these menrarals, they’re beneficial to Farm Productivity and the health of the soil –nd as a bonus, there’s the carbon removal. “

Approximately one ton of magnesium oxide and calcium silicate could absorb one ton of co2 from the atmosphere –nd that Estimate Accounts for the Co2 Emitted by the Kills, the Kills, the Kill Request Than half the energy used in other carbon capture technologies.

Scaling this solution to an impactful level, however, would require millions of tons of magnesium oxide and calcium silicate, annually. Nevertheless, Chen Points Out that If Estimates of Natural Reserves of Magnesium Silicates Such as Olivine or Serpentine are Accurate, they all be enough to remove all the Human-specialized ATMONCHRIC O. And then some. Additionally, the silicates also be recovered from mining tailings (mining Leftovers).

“Society has alredy Figured out how to produce bills of tons of cement per year, and cement kilns run for decades,” Kanan Said. “If we use thos learnings and designs, there is a clear path for how to go from lab discovery to carbon removal on a meaningful scale.”